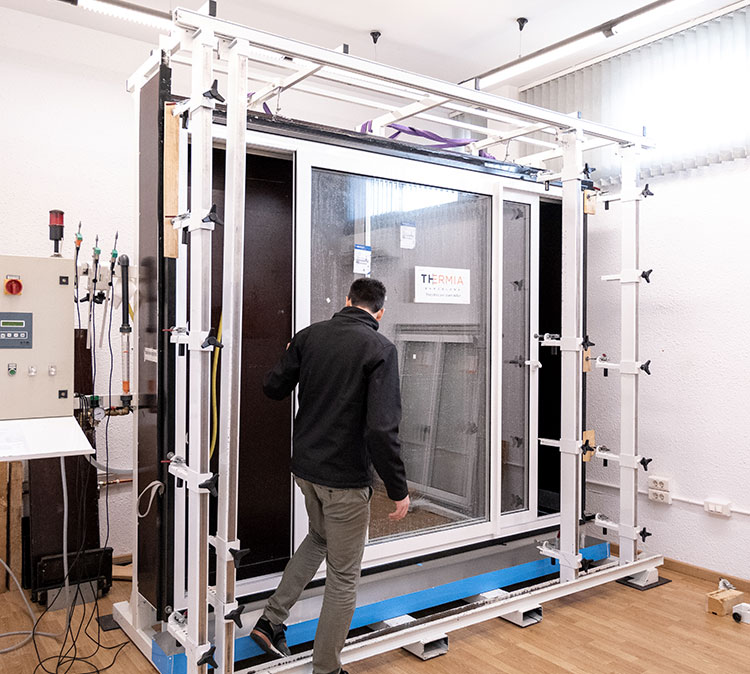

All Thermia Barcelona enclosure systems for the production of Thermia aluminium windows are designed and tested in strict compliance with European market regulations, which require high performance in terms of airtightness, durability and performance in inclement weather, together with maximum energy savings.

The quality of Thermia Barcelona windows.

Getting the details right.

MANOEUVER COMPONENTS AND ACCESORIES

Manufactured pursuant to the ISO 9001:2008 quality management standard and ISO 14001:2004 on environmental management and EN1670; ISO4628-2; ISO10289; ISO 2081 in terms of exposure to corrosion in a salt-spray chamber (240 hours).

- Casement, outwards opening, and tilting cremone fittings: pursuant to EN 13126-1 and four 25,000 test cycles. Comprising cast aluminium and stainless steel.

- Tilt and turn fittings: Pursuant to EN 13126-1 and four 25,000 test cycles, and weight of up to 130 kg/leaf.

Made with high-density zamak with an anti-corrosion treatment and stainless steel. - Multi-point fittings for sliding systems: Pursuant to EN 13126-1 and four 25,000 tests cycles.

- Projecting stay hinges: Pursuant to EN 13126-1 and four 25,000 tests cycles. Made of stainless steel.

- Pressure closing devices: Pursuant to EN 13126-2 and tested to 25,000 cycles.

- Window hinges (A0003120): Pursuant to EN 13126-1 and four 200,000 test cycles. 70 kg loads. (2 hinges) and 90 kg. (3 hinges). Comprising extruded aluminium and stainless steel.

- Door hinges (A0003130): Pursuant to EN 13126-1 and four 200,000 test cycles. 90 kg loads. (2 hinges) and 110 kg. (3 hinges). Comprising extruded aluminium and stainless steel.

-

Closing devices: Pursuant to UNI EN 12209 for the range of 1 side closing devices and EN 15685 for multi-point closing devices.

-

Main frame and leaf closing elements: Pursuant to EN 13126-1 and UNI EN 12051 – Tested at 10,000 cycles.

AIRTIGHTNESS AND WATERTIGHTNESS ELEMENTS AND ACCESSORIES.

Pursuant to ISO 9001 on quality management and manufactured pursuant to ISO 3302 on tolerances and UNE EN 12635

Sealing and glazing gaskets: Manufactured in EPDM 70 SHORE rubber of the highest quality, resistant to weather and UV rays.

- Brush weather-stripping: Pursuant to AAMA 701 and 702, manufactured using textured, siliconised multifilament polypropylene yarn stabilised against UVA rays, with a middle non-woven fabric sheet. Brush weather-stripping ultrasonically welded to the stiff polypropylene base.

- Air seal: Extruded, anodised and made-to-measure aluminium base. Textured, siliconised multifilament polypropylene yarn stabilised against UVA rays, with a middle sheet.

BUILT-IN CLOSING DEVICES FOR SLIDING FIXTURES

Pursuant to EN 1670. Tested at SGI International for 20,000 cycles.

BEARINGS FOR SLIDING FIXTURES

Manufactured pursuant to ISO 9001 on quality management and UNI EN 13126-15. Tested for 10,000 or 25,000 cycles depending on the reference.

OTHER ACCESSORIES (Plastic moulded parts pertaining to the system)

Manufactured pursuant to ISO 9001 on quality management.

- Decorative elements: Polyester materials, high-density PA6 polyamide.

- Functional elements: PA6+TPE, polyamide and fibreglass.

Contact

Contact